Basic Tips

Read your sewing machine manual and go back to it as needed.

Always turn the handwheel TOWARDS you in a counter-clockwise or anti-clockwise direction. Like most brands of sewing machines, turning the handwheel away from you in a clockwise direction can damage the sewing machine and affect the timing, creating expensive repair bills.

Always thread the sewing machine with the needle in the highest position and the presser foot raised.

Always be sure the presser foot is down when you start sewing.

Change sewing needles after 8 hours of use. Schmetz Needles provides information on signs that a change in needles is needed as well as a needle guide to help select the right needle for each project.

Always use a class 15 bobbin for all EverSewn sewing machines. Using the wrong bobbin can cause damage.

Other questions

Q. I live outside of the US can I purchase an EverSewn sewing machine?

All EverSewn models are 120v and not compatible with the voltage in many countries. The machines have not been tested with any type of converter so we cannot guarantee performance if one is used.

(Sparrow X 120V ~ 60Hz 0.6A)

Q. Do I need to oil my Sparrow sewing machine?

You do not need to oil your Sparrow machine. We do recommend regular cleaning of the bobbin area and annual “checkups” with a trusted sewing machine shop. They will ensure the inner workings of the machine are cleaned and lubricated. For general cleaning and maintenance, you should be able to take the machine to any trusted sewing machine repairman. If you are experiencing an issue that you believe may be a warranty issue we ask that you call EverSewn and we can assist you directly.

Q. Where can I buy EverSewn accessories and sewing machines?

We do not sell items directly. You would need to purchase through a local dealer. There is a store locator on the EverSewn website to assist you. If there are no shops near you, you can order online from one of the following: allbrands.com, sewvacdirect.com, or missouriquiltco.com

Q. What kind of shank does EverSewn have?

All of the EverSewn machines are low shank machines. Typically any low shank snap-on foot “should” work. If you prefer to purchase an EverSewn branded foot, you would need to purchase through a local dealer. There is a store locator on the EverSewn website to assist you. If there are no shops near you, you can order online from one of the following: allbrands.com, sewvacdirect.com, or missouriquiltco.com

Troubleshooting Tips

Q. Why are there huge loops of thread on the back of the fabric?

Check that the machine was threaded correctly. The upper thread is not correctly placed in the tension mechanism or take-up lever. To fix this rethread the machine. Completely remove the thread and start over with the presser foot lifter raised and the needle in the highest position (turn TOWARDS you). Having the presser foot lifter raised and the needle in the highest position will open the tension disks, allowing the thread to be properly installed.

Q. Why won’t the hand wheel rotate?

There is thread caught in the hook of the bobbin area. Turn off the machine. Remove the bobbin case from the machine. Lubricate the hook. Gently rotate the hand wheel back and forth. Remove the thread caught in the hook.

Q. Why isn’t my bobbin winding evenly?

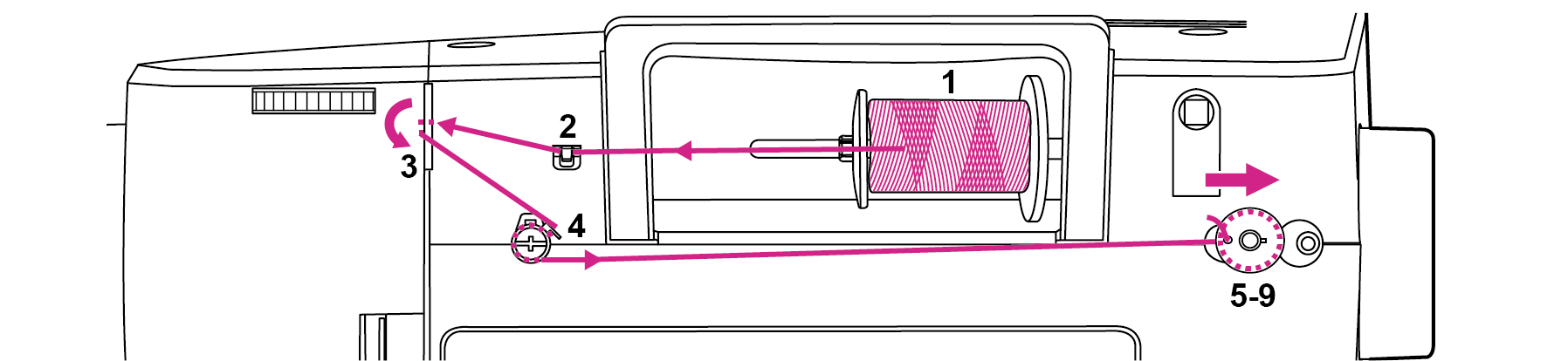

It’s possible that the thread did not properly engage with the bobbin winding tension spring which looks like a metal button on the top of the machine (Step 4). The thread should almost click into place. Check your manual and/or the diagram on the top of the machine to make sure that the thread is following the proper path for winding. Feed the thread through the hole in the top of the bobbin and hold the tail while winding until you can safely cut the tail off without risking the bobbin unwinding. National Sewing Circle has a great video on winding bobbins, however each machine is different so make sure to follow the manufacturer’s instructions.

Q. Why does my EverSewn Sparrow QE pause and make a “brrr” noise when starting up?

This noise is the machine doing a self-check and calibrating itself before starting to sew.

Q. Needle breaks?

Be careful not to pull the fabric when sewing. Make sure the correct needle size and type is being used. Ensure that the needle has been correctly installed with flat side to the back and pushed all of the way up. Check to see that the stitch and presser foot are correct for the stitch that you are using, some will not allow for zigzags and offset stitching. Make sure that you haven’t accidentally bumped a button causing the machine to switch to an offset stitch. Turn the machine off and back on to reset for straight stitching.